![]() It’s Time to bolt! This article originally appeared in my earlier blog site.

It’s Time to bolt! This article originally appeared in my earlier blog site.

We seek information…

You won’t get it!

By hook, or by crook, we will!

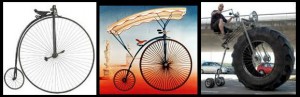

This quickie model was something I put together largely to experiment with the CS boiler segments, and to try a specific building technique. The model is a very simple one, and is supposed to represent an old penny-farthing style bicycle (below, far left). Construction took just over an hour. Most of that time was taken up by the spokes in the main wheel.

These old bikes aren’t very common today, but I’ve seen some from time to time. The owner of a local bike shop rides one during the annual Forth of July parade. The most famous penny-farthing in history is perhaps the one from the British television series “The Prisoner.” (center)

The true penny-farthing had only two wheels, but my model has three so that it wouldn’t keep falling over. The size was such that one of my daughter’s Barbie dolls could sit comfortably on the seat and “ride” around the play room. Sadly, the awning over the seat kept getting in the way, so it was removed in short order.

The large wheel is made from a set of CS curved boiler sections, which is too thick for a true penny-farthing. I guess this would have to be a “mountain bike” variant (above, far right). Anyway, the spokes were made from “I” perforated strips and a pair of CR hub turret plates. I have some other ideas for models that feature a spoked wheel based on the CS sections; this model was my proof of concept. The combination of parts worked perfectly.

Real penny-farthings are steered by a direct steering bar on the main wheel, just as with modern diamond-frame bicycles. This model can be “steered” the same way, at up to a 70-degree angle. I understand that a real penny-farthing has a similar limitation. I suspect that taking a turn too tightly on one of these things would be a painful experience!

This was a simple, but fun little model. The biggest problem with it was keeping the wheel fork tight. The seat and back wheel carriage had a tendency to “kick out” behind the large wheel, and required frequent tightening. If I ever make this model again, I’ll use a pair of 8-32 wing nuts, or a pair of thumb-tap screws, to hold the wheel fork.